Digital Printing Fabrics Shining with Satin

Satin first appeared in Europe in the 12th century in Roman Italy.

However, in those days, satin was a smooth silk fabric with a sheen.

Over the next two centuries, satin fabrics woven from silk or cotton fibers, developed by Chinese craftsmen who noticed that the more the yarn was twisted, the brighter the fabric was, and was brought west by sea from a port city in China called Zaitun.

The "zaytun" fabrics, named after the place of production, later turned into "satin" fabrics named after the French.

Satin symbolized wealth, luxury and nobility in those centuries.

KW 026 EMERALD which is 100% Polyester, satin fabric. It is mainly made for Transfer and Direct Sublimation printing.

The weight of EMERALD is 90 gram per sqm (3,1 oz per square foot) and its maximum width is 150 cm (59 inches).

EMERALD is popular for Scarf / Flag / Interior Decoration such as table cloths and pillow.

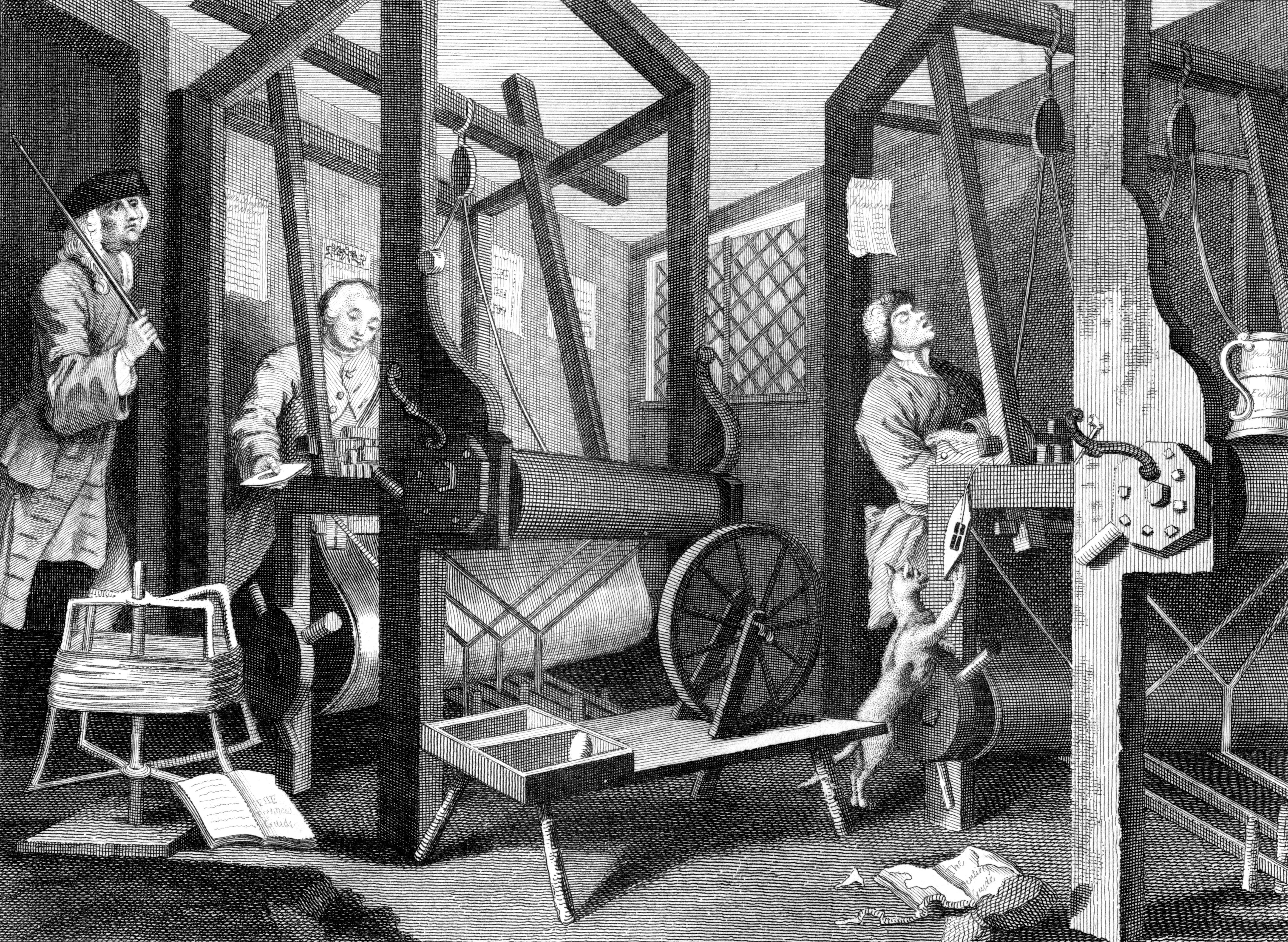

In the 17th century, a circular machine that weaving tubular satin was invented in France.

Satin products gradually began to replace handmade products because machine production took much less time.

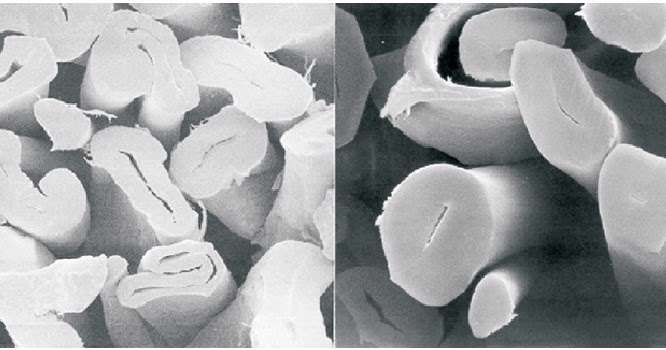

The mercerization process was invented by the English scientist John Mercer in the mid-19th century, this technology only gained popularity towards the end of the century.

Mercerization means that finished fabrics acquire a shine when treated with an alkaline solution. Although this reduced the amount of fabric, it added easily dyeability as a new feature.

The mercerization process changes the structure of the cotton fabric, making the yarn swollen, dense and durable.

In the era of industrialization, satin production technology has changed. Cotton was added to its structure, it was even made from cotton, which significantly reduced the cost of production and also gave this fabric greater durability.

Today, the mercerization process is used together with the technologies developed for the production of satin fabric.

KW 007 DIAMOND GLOSSY which is 100% Polyester, knitted glossy satin fabric.

It is mainly made for Direct and Transfer Sublimation printing.

The weight of DIAMOND is 175 gram per sqm (6,2 oz per square foot) and its maximum width is 310 CM (122 inches).

DIAMOND is popular for Flag / Banner / Interior Decoration such as table cloths, curtain and pillows.

The weave of the threads in the fabric allows you to give satin fabrics a pleasant to the touch shine and smoothness.

Therefore, satin fabrics are very popular in interior decoration (curtains, tablecloths, pillowcases).

Our matte satin fabric KW 008 DIAMOND MATT is 100% Polyester, knitted satin fabric suitable for digital printing as a tablecloth.

It is mainly produced for with Direct and Transfer Sublimation printing.

DIAMOND weights 175 grams per m² and has a maximum width of 310 cm.

Satin fabrics are a wide group of fabrics that can be woven in a variety of ways, based on a special woven yarn technology.

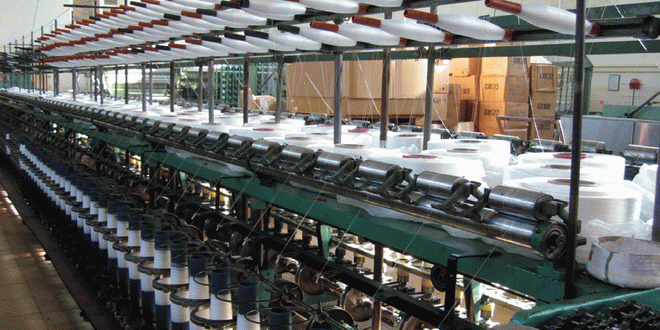

The best for satin is yarn from spinning machines. When producing satin, the effect of twisted threads are being used.

The more the yarn is twisted, the brighter it shines and the denser the surface texture.

This yarn is much stronger than the yarn obtained in rotary machines.

Our Best Seller Eco Satin fabric which is KW 047.

It is a woven fabric and made of %100 Polyester yarn.

KW 047 is mainly made for direct and transfer sublimation printing.

At the same time, it is also suitable for UV and Latex printing.

The weight is (140 gr per sqm ) and the maximum width of KW 047 is (320 cm).

Due to its high yarn count, specific ratio of weft and warp yarns and finishing processes, satin gains its characteristic feature and silky shine.

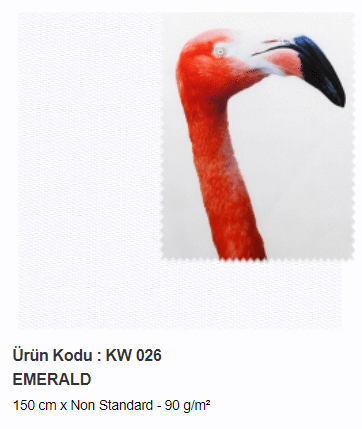

KW 011 RUBY which is %100 Polyester, woven satin fabric.

It is mainly made for direct and transfer sublimation printing.

It is also suitable for UV and Latex printing.

The weight of KW 011 is (165 gr per sqm) and its maximum width is (320 cm)

Our Fabric Types Suitable for Backlit and Other Digital Printing

Soletex offers the best solution for the digital printing industry with its more than 15 years of research and development (R&D), advanced technology machinery and know-how.

Soletex Digital Printing Fabrics is the go-to supplier for backlit and other digital printing fabrics needs of advertisers and marketers around the world.

Lightbox: Used for numerous promotional applications such as Banner, Indoor Decoration, Display - Promotion, Fair Applications, Inflatable Fabrics with Internal Lighting and more.

With our quality, large format and long-length backlit fabrics, we produce innovative digital printing fabrics.

From start to finish, we cover all the steps of production including warping, knitting, coating, cutting and packaging as well as finishing, graphic, digital printing and accessory production.

Our product range, produced in accordance with digital printing technologies, includes flag, satin, display, backlit, canvas, blockout, decoration fabrics and more.