Digital Printing Blockout, Blackout, Black Back Fabrics

Blockout fabrics contain a black layer.

Blockout fabric consists of 3 layers, are blackout curtain fabrics where the top and bottom layers are colored or white and the layer in between is black. Blockout fabrics have double-sided textures.

These fabrics are designed to protect against the sunlight at the maximum level, to withstand its effects and to provide insulation against outdoor heat and cold.

Blockout fabrics, which have sound absorbing properties as well as absorbing light, it gets their sound insulation feature from the production of double layers. Blockout fabrics provide ease of use with their resistance to stains.

Blockout fabrics, where shrinkage and fading are very low, are among the most preferred fabric types, as they are easy to use.

Where to use Blockout Fabrics?

Blockout fabrics can be used in places where we want to block the light.Blockout fabric is a type of fabric widely used for curtains and roller blinds.

Usage area as roller blinds; hotels, homes, nursing homes, schools, kindergartens and hospitals.

The use of background is also common in places where works such as projection presentations are made.

Blockout fabrics preferred in bedrooms are a useful option as they will prevent sleep interruptions due to the sun.

Blockout fabric types are also known as sleep curtains with this feature.

Due to the texture of the fabric in blockout curtains, a decrease in the darkening effect can be observed as the color becomes lighter.

Backdrop curtain fabrics are easier to wash and sew, as they have a softer texture compared to roller blind fabrics.

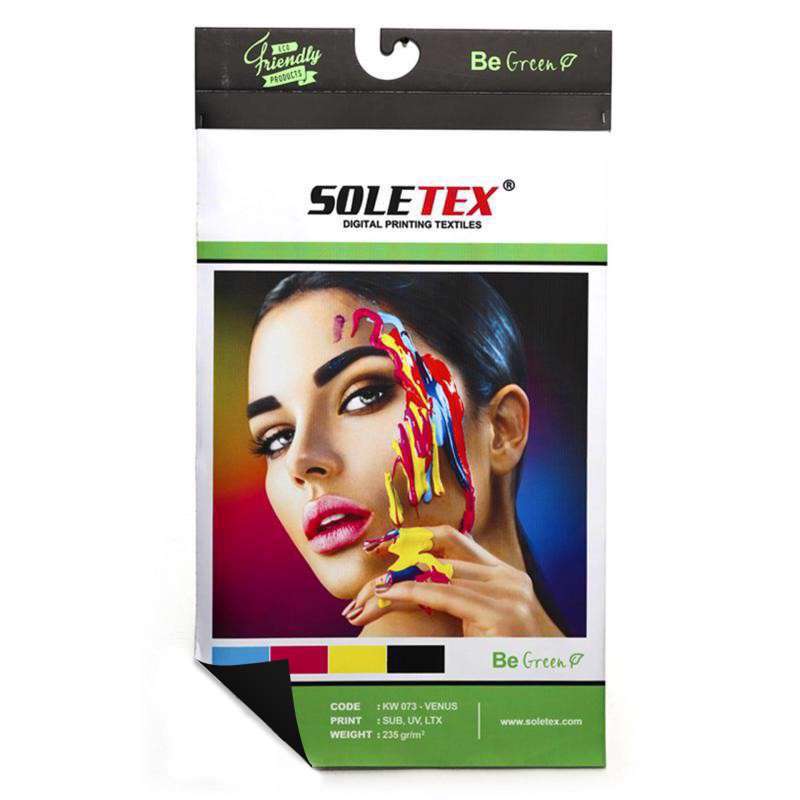

VENUS (Black Back) is our 100% Polyester, knitted blockout fabric, which is one of our most suitable fabrics for digital printing for roller blinds.

It is mainly produced for direct and transfer printing. UV and Latex printing can also be done.

The weight of VENUS is 235gr per m² and its maximum width is 320 cm. Our digital printing fabric for another roller blind application with a white back is called KS 002 MERCURY 100% Polyester, knitted blockout fabric.

It is mainly produced for UV and Latex printing.

MERCURY has a weight of 300 g per m² and a maximum width of 320 cm.

Our Blockout Fabrics Suitable for Advertising Industry Other Than Roller Blind Application

Another area that greatly benefits from this fabric is roll-ups and front-lit banners.

KW 060 - MOON (Grey Back)

It is 100% Polyester, knitted blockout fabric. This grey backed fabric is coated on one side to prevent shadow reflection and light show. Mainly produced for direct and transfer sublimation printing, but also suitable for UV and Latex printing.

The KW 060 has a weight (235 g per m²) and a maximum width (320 cm).

It can also be used as a background and stage decoration fabric, it is an ideal fabric to prevent shades and shadows.

KS 048 - JUPITER (Black Back)

It is a 100% polyester knitted fabric and a special black coating on the back side of the fabric to prevent shadow reflections.

Suitable for UV, Latex, Solvent and Eco Solvent printing.

The weight of the KS 048 is (240 g per m²) and its maximum width (320 cm).

You can reach out to our other Blockout and Black back fabrics produced for all digital printing by clicking here,

You can learn more about fabrics suitable for the area of use you are looking for as well.

How Did Blockout Fabrics Come About?

Blockout fabrics were first designed in England during the Second World War.Their purpose was to prevent Nazi pilots from seeing the light from occupied buildings.

Since their lives were at stake, they designed their blockout fabric with layers of black cotton fabric to block out the light.

Because the light passing through the windows put people at risk of being bombed.

It was designed to prevent the inner light from shining outward.

The Process of Producing Blockout Fabrics?

Blockout Coating, consisting of various textile surfaces (woven, knitted, nonwoven), is the transfer of chemicals in liquid, paste or powder form to the fabric in transfer forms such as powder, paste, foam, depending on the desired effect on one or both sides of the floor fabric, and in this way, a film on the fabric. It is a textile process made in the form of forming a layer.

The effectiveness of the blockout fabric is measured in 'transition'.

This refers to the layers and linings added to the fabric to achieve the blackening effect.

It leaves two coats of white and one coat of black foam in three passes. It can be used as a three-pass fabric as the black layer is not visible.

What are the Technical Specifications?

- Mainly made from 100% polyester.

- Besides blocking light, blockout fabrics are insulating and have noise-damping qualities due to their density and opacity.

- It is opaque up to 99%.

- It is wrinkle resistant because it is polyester.

- It can be machine washed at 30 degrees.

- Different colors can be produced.

- Doesn't pull.

- It does not fade easily.

- Apart from curtains, it is also used in the production of tablecloths, cushions and bags.

- It is widely used for blackout purposes.

- Blockout Fabrics are also fire retardant.

- Flame retardant fabrics are chemically treated to achieve high flame resistance.

- The front surface of the blockout fabric is white as in other fabrics.Therefore, four colors are suitable for digital printing.

- Blockout Fabrics can block out noise. Blockout Fabrics can help save energy.

Features to Look for in a Good Perfomance Blockout Fabric

- Optical - Light Transmittance

- Thermal - Thermal Insulation

- Brightness

- Break/Elongation

- Tearing

- Explosion Abrasion/Martindale abrasion

- Adhesion

- Washing resistance

- Fabrics that pass these tests are called successful blockout fabrics.It can also be applied to blockout fabrics when the desired chemicals are applied to the fabric in the following special tests.

Special Tests

• Power Flammability - Flame Retardant• Water repellency / Spray test (AATCC 22)

• Oil Repellency (AATCC 118)

• Dirt and stain repellency

• Light Fastness/ Xenon test

• PN 410 Test

• Bundesmann Test (DIN53888)

• Waterproof (ISO20811)

• Bending strength/ Crumple Flex

• Bally flex test ISO7854/B

• Seam strength (ISO13935-2)

• Heat transfer radiation ENISO6942

• Heat transfer index

• High visibility ENISO20471

• Surface conductivity

• Puncture resistance (EN863)

• Water vapor permeability (ASTME 95 / 96)

How to Clean the Blockout Fabric?

It can be carefully wiped using a slightly damp sponge or cloth.It is then rinsed. Blockout curtains can be cleaned without removing them.

By attaching a suitable equipment to the vacuum cleaner, it can be easily cleaned by moving it over the curtain.

Our Fabrics Suitable for Blockout and Black Back Applications and Other Digital Printing

Soletex offers the best solution for the digital printing industry with its more than 15 years of research and development (R&D), advanced technology machinery and know-how.

It is used for numerous promotional applications such as roller blinds, rollups, banners, frontlit, background fabric, stage decoration and more.

With our high quality, large format and long-length blockout fabrics, we produce innovative digital printing fabrics.

From start to finish, we cover all the steps of production with warping, knitting, coating, cutting and packaging as well as finishing, graphic, digital printing and accessory production. we cover.