BACKLIT – LIGHTBOX DIGITAL PRINTING FABRICS

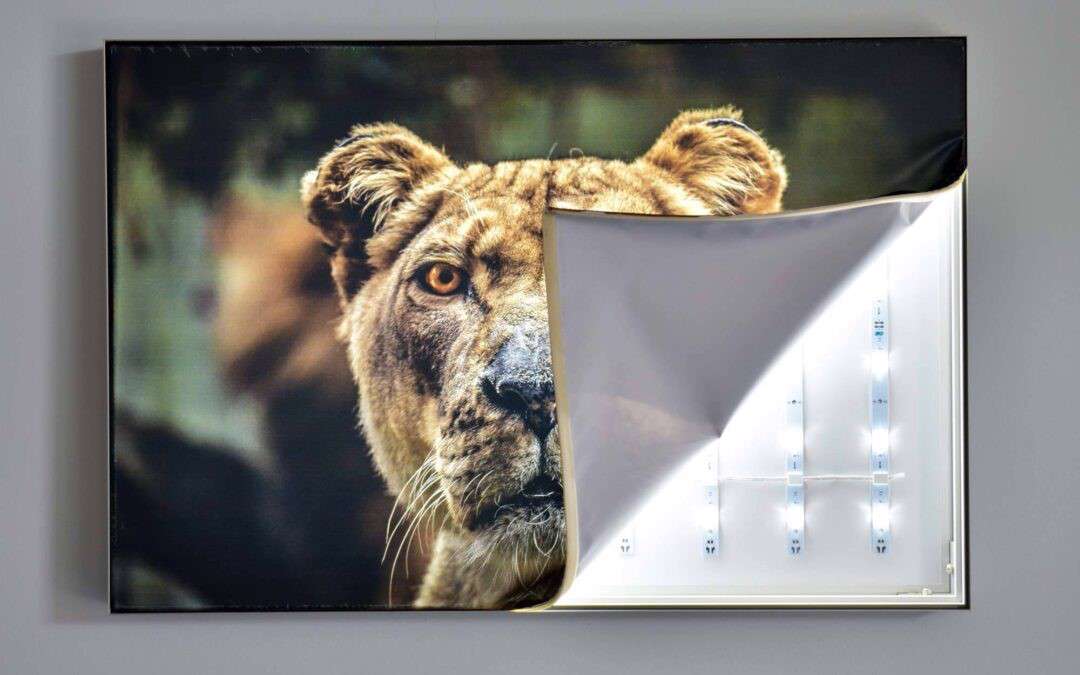

Illuminated fabric systems, After the digital printing process, it comes out to be mounted inside the frame by using sewns from the fabric. An effective advertisement - promotion preference comes.

This system design will backlight and effectively showcase the logo or message. For backlit fabrics, there are different fabric options with different textures, weights and translucency levels.

You can check out all Soletex Backlit Fabrics from here.

In terms of energy saving, LED lights require less power than fluorescent or neon tubes. It is known that LED lights illuminate thousands of hours more than the types of lighting used in other backlit frame systems.

As for the usage areas of backlit fabrics,

Over the past decade, we have witnessed an increasing trend in trade fair areas, popup stands, menu boards, display light boxes, signage, banners, kiosks, art exhibitions, display cases, fairs, in-store spaces.

Backlit - Lightbox fabrics are environmentally friendly advertising and promotion choice as they create less waste with the production methods used.

You can move backlit fabrics freely to find the best positioning and display them most effectively because of its lightweight and versatile structure.

BENEFITS OF BACKLIT FABRIC

Creating a backlit advertising area that you prefer, in generally dim areas, will make this area different from other areas and will naturally attract attention with its light effect and allow you to create an effective and striking advertisement.The ambiance that will emerge with the meeting of high-quality graphics and vivid colors with light will both keep the environment alive and draw the attention of your exhibitors and potential customers directly to you.

First impressions become even more important for businesses at trade shows. Showcasing your products or services at a trade show is not just about welcoming visitors, it's also about presenting your brand in an attractive and memorable way. The appearance of your exhibition can attract attention and attract more visitors to your booth.

These types of trade shows not only promote your business but also create a professional appearance at large events.

You can use your digitally printed fabric for new promotional purposes, use at your next trade show or rebrand, simply by changing it to the same frame's dimensions.

Considering the versatility of backlit fabric and frame systems,

These products, which are used repeatedly, offer you a very practical solution when you want to change your advertisement image.

From an ecological point of view, rather than production, another advantage is the use of printing technique.

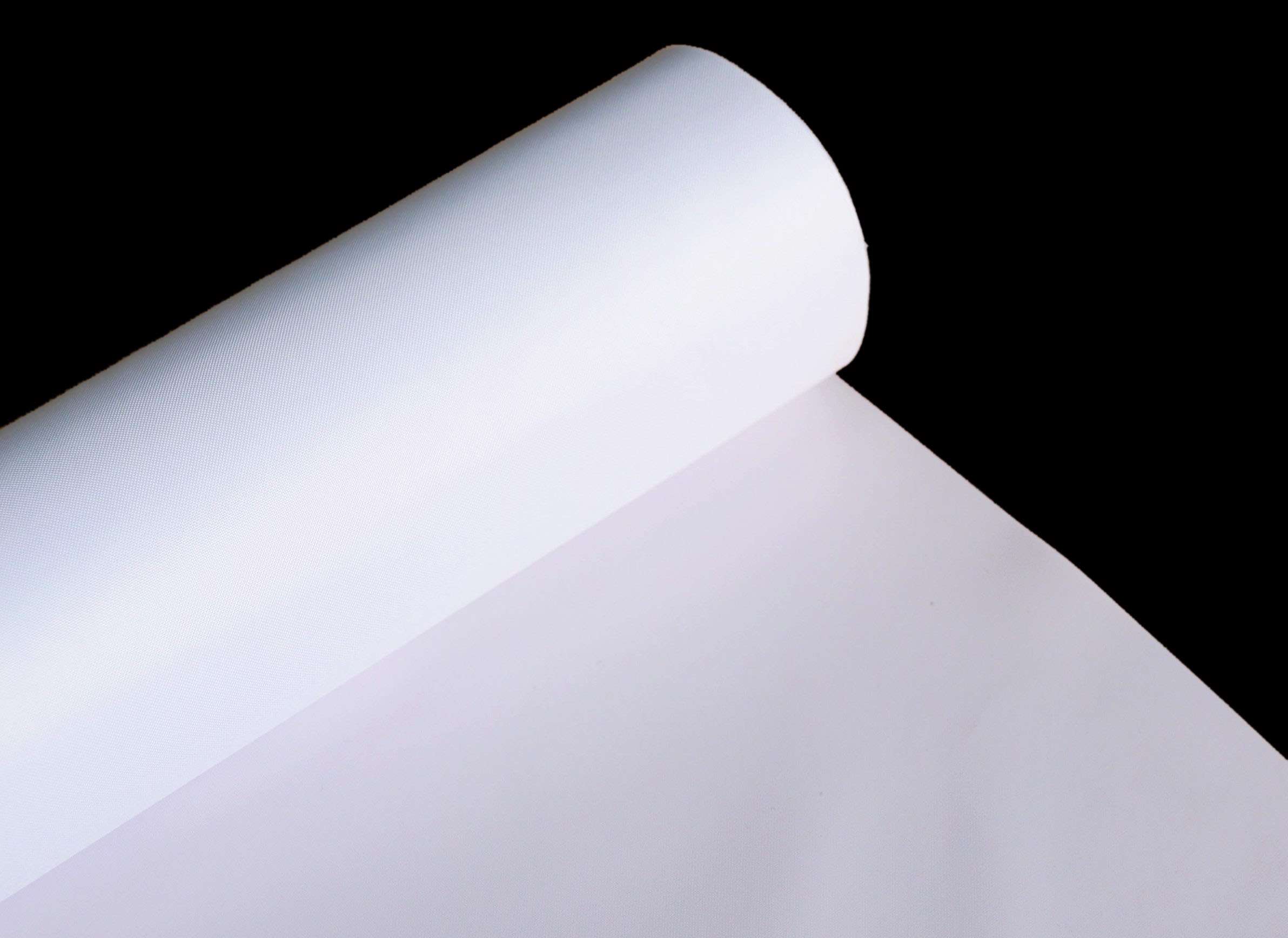

The following 2 products that we have worked on and finalized are produced for direct sublimation printing.

KW 067 - QUEEN

310 cm x 50 mt - 175 g/m²

Note: For other printing types, you can find our backlit fabrics here. (Transfer, UV, Latex and Solvent)

Direct Sublimation Printing,

It is simple and fast compared to screen printing and other printing techniques. It is a digital printing technique that is used more in the commercial printing and signage industry.

Direct Sublimation Printing Advantages

Digitally printed with water-based inks that will interact with heat to produce a vibrant and detailed print image, it is a two-stage fabric printing process where the synthetic top layer interacts with the dye and then the printed top layer reacts with heat to bring colors to life.

How Does Direct Sublimation Printing Work?

Sublimation inks react with heat and pressure to turn the ink into gas. When heat is applied, the pores of the fabric open, allowing the gaseous dye to flow into the open pores. As the substrate cools, its pores close and permanently trap the inks into the fabric. The process results in consistently vibrant, photographic hues as gaseous inks enter the pores of the substrate rather than build up on the surface. Dye sublimation printing is the two main methods of transfer printing and direct dye printing.

Transfer Printing

The press prints on transfer paper with a coating designed to hold and then deposits the printed image onto the surface of the fabric in a heat press, under heat and pressure.

When the print on the transfer paper is contacted with the fabric in the heat press, the ink embedded in the paper is converted into a gas and penetrates directly into the fibers of the fabric.

Direct Sublimation Printing

Direct sublimation printing eliminates the need for transfer paper as inks are sprayed directly onto the top layer of the coated fabric.

Printed fabrics still need to be run through a heat roller for the sublimation process to fix the dye to the fabric.

What are the Differences Between Transfer and Direct Dye Printing?

Direct sublimation printing penetrates further into the fabric, allowing the color to migrate to the back side of the fabric.Transfer dye printing inks sit on the fabric and this allows the threads to be seen when the fabric is stretched, in this case, it will cause the backlight to be visible, especially when considering backlit fabrics and usage areas.

Since the inks of direct sublimation printing fill the gaps between the threads, it will not allow the passage of spaces and light beams, and will reveal a much clearer and sharper image.

Direct Sublimation Printing Is It Really Eco-Friendly - Sustainable?

Direct sublimation printing uses water-based dyes and is the most sustainable method as it eliminates the use of paper in the printing process.

Our Fabric Types Suitable for Backlit and Other Digital Printing

Soletex offers the best solution for the digital printing industry with its more than 15 years of research and development (R&D), advanced technology machinery and know-how.

Soletex Digital Printing Fabrics is the go-to supplier for backlit and other digital printing fabrics needs of advertisers and marketers around the world.

Lightbox: Used for numerous promotional applications such as Banner, Indoor Decoration, Display - Promotion, Fair Applications, Inflatable Fabrics with Internal Lighting and more.

With our quality, large format and long-length backlit fabrics, we produce innovative digital printing fabrics.

From start to finish, we cover all the steps of production including warping, knitting, coating, cutting and packaging as well as finishing, graphic, digital printing and accessory production.

Our product range, produced in accordance with digital printing technologies, includes flag, satin, display, backlit, canvas, blockout, decoration fabrics and more.